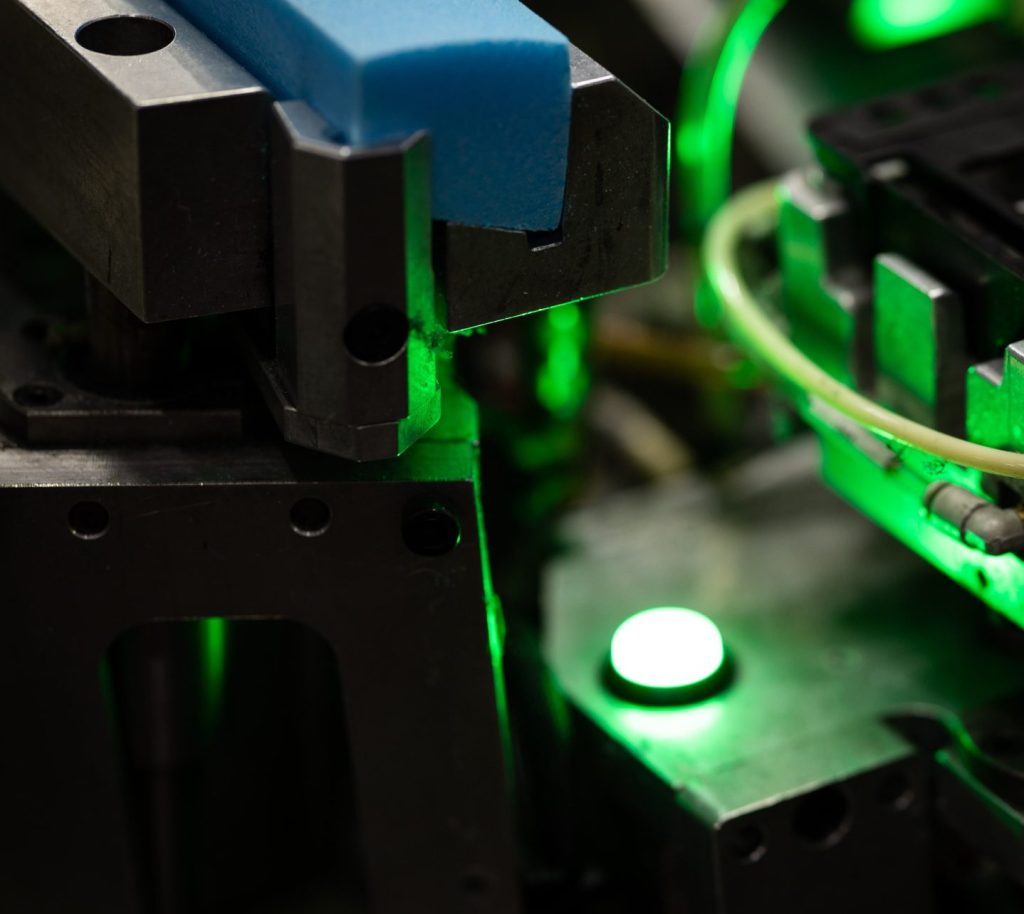

Engineered Precision

for Seamless Support.

Engineering Approach

Smart engineering for rapid and seamless innovation.

Engineering isn’t just a function at CLI – it’s the foundation of everything we do. Our highly engineered solutions are designed to optimize warehouse operations, enhance manufacturing support, and ensure our customers achieve maximum efficiency, cost savings, and responsiveness to change.

Our engineering approach aligns with our Plan for Every Part (PFEP) methodology and the quality principles of W. Edwards Deming, ensuring continuous improvement and operational excellence. By integrating data-driven strategies, lean methodologies, and real-time responsiveness, we help OEMs and Tier-1 suppliers stay ahead of shifting production demands.

Our Engineering Approach

Every facility, production line, and material flow present unique challenges. That’s why CLI develops tailored engineering solutions to ensure:

- Optimal Space Utilization

Engineering precise layouts that maximize storage capacity and parts flow. - Demand-Driven Inventory Management

Analyzing SKU mix, demand variability, and min/max inventory levels to eliminate bottlenecks. - Productivity Optimization

Using “circle of work” techniques to position materials for high-runner/low-runner efficiency. - Synchronized Workflows

Creating flexible, agile solutions that adapt to evolving OEM and Tier-1 production requirements.

By leveraging data analytics and industry best practices, our highly engineered solutions drive efficiency, accuracy, and productivity at every stage.

Synchronous Manufacturing Support.

For synchronous manufacturing operations, precision is everything. CLI’s engineering expertise ensures that every process is designed for efficiency, speed, and adaptability.

Our engineering-driven approach enables us to:

- Implement Solutions on Time

Ensuring fast, efficient rollouts with built-in productivity enhancements. - Respond to Change Instantly

Designing processes that adapt to real-world manufacturing shifts without disruption. - Maximize Cost Savings

Engineering efficiencies that eliminate waste, reduce downtime, and optimize resource allocation.

Through a combination of lean process engineering, real-time analytics, and expert execution, CLI provides scalable solutions that support just-in-time manufacturing with predictable reliability.

Managing & Responding to Change.

In today’s manufacturing and logistics environments, change is constant. At CLI, our engineering approach is the foundation of proactive change management, ensuring seamless transitions while maintaining operational stability.

Our formal change management process follows a structured approach:

- Identification & Analysis

Changes are logged and assessed for impact on resources, cost, and processes. - Engineering-Led Execution

Our team updates work instructions, PFMEA, and process control plans to reflect new standards. - Irreversible Corrective Actions

We implement long-term solutions that prevent recurrence and drive continuous improvement.

With engineering at the core of our change management strategy, we provide structured, data-backed solutions that keep operations running smoothly – no matter what challenges arise.

Give us your toughest challenge.

What variables have you struggled to control in your process? Our expert problem solvers are ready to listen. Reach out to CLI today.

Contact Us