Value Added Assembly

Value Added Assembly

Precision assembly for complex applications.

In today’s fast-paced manufacturing environment, efficiency, accuracy, and seamless integration are essential. Original Equipment Manufacturers (OEMs) seek to outsource highly complex sub-assemblies for many reasons, driven to enhance quality, reduce waste, and improve profitability of their operations.

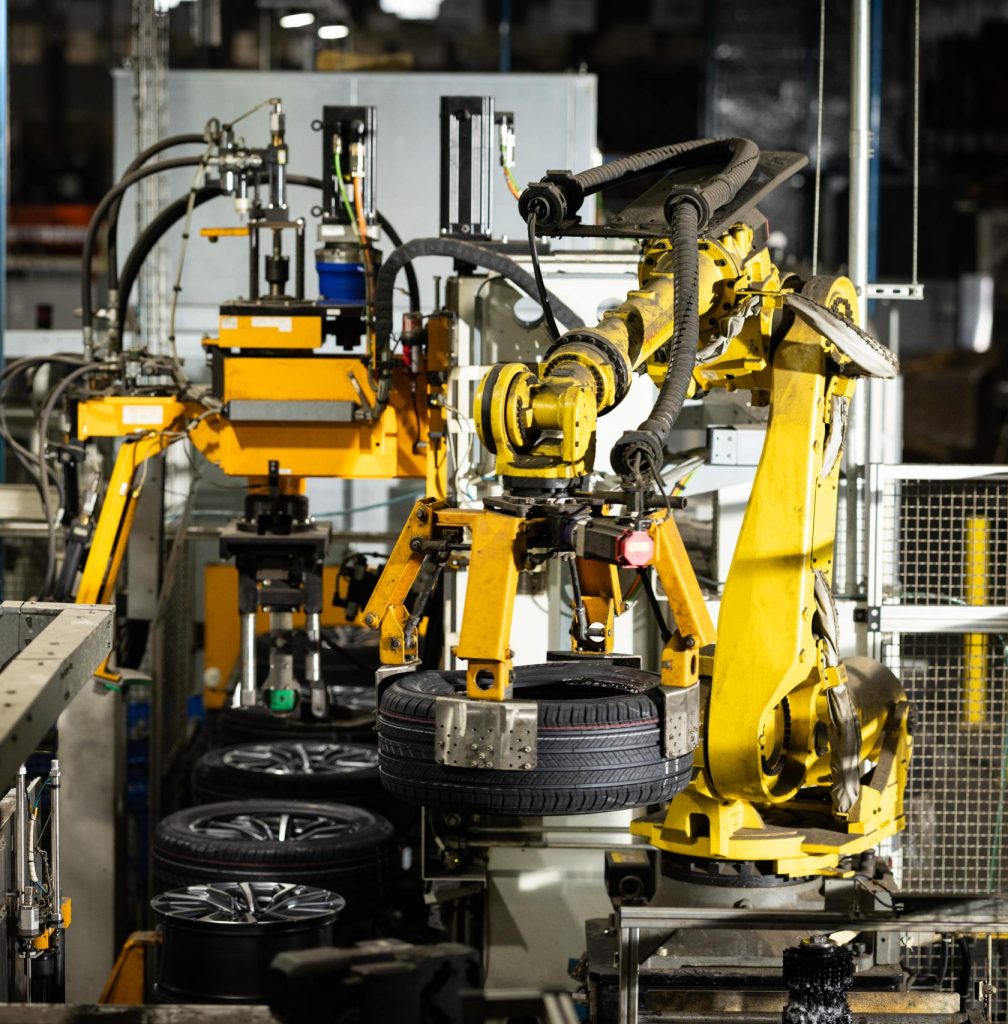

Our synchronous sub-assembly services are engineered to handle the most intricate product configurations, with build variations ranging from three to thousands of unique assemblies. Annually, CLI assembles more than 4 million sub-assemblies, supporting manufacturers across multiple industries with precision, scalability, and reliability. Each of these sub-assemblies has a dedicated process, leveraging advanced robotics, automation, error-proofing, and quality control systems to deliver unmatched reliability and performance.

Supporting Sub-Assembly Needs Across a Broad Array of Industries

CLI’s Value-Added Assembly services deliver highly complex sub-assemblies for a diverse range of OEMs, including automotive, truck, recreational vehicle, appliance, or any industry requiring fastening or gluing operations. By integrating seamlessly into our customers’ production processes, we enhance efficiency, reduce cycle times, and ensure just-in-time delivery of critical applications.

Advanced Assembly Methods

We deploy a variety of cutting-edge assembly methods to accommodate the unique needs of each OEM:

- Fully automated builds using robotics and programmable logic controller (PLC) systems.

- Hybrid conveyor builds that combine manual and robotic assembly, torque monitoring, and PLC controls.

- Sequenced manual station builds for step-by-step precision assembly.

A Synchronized, Data-Driven Process

Our sub-assembly process is powered by a fully integrated ERP system and real-time line controllers, ensuring error-proof, synchronized production.

- A pull signal from the OEM initiates the automated pick process.

- Error detection systems ensure compliance with tolerances as small as 40 microns—thinner than a human hair.

- Assembled units are placed into custom-designed reusable containers for just-in-time, lineside delivery to the OEM’s assembly plant.

Rigorous Error-Proofing for Uncompromising Quality

Quality and precision are at the core of CLI’s Value-Added Assembly operations. We employ rigorous error-proofing techniques to ensure flawless execution:

- Scan guns, pick lights, and light screens to verify correct part installation.

- Vision systems, laser-placement guides, and proximity sensors to ensure part presence, location, and orientation.

- Statistical process control software for predictive error detection.

- Torque and angle readings tied to final assembly barcodes.

- Digital probe master part gauges for real-time adjustments.

- Daily calibration of assembly tools to maintain optimal performance.

With millions of builds, multiple part variations, and robust quality control, CLI has refined its sub-assembly processes to meet the exacting standards of manufacturers worldwide.

Give us your toughest challenge.

What variables have you struggled to control in your process? Our expert problem solvers are ready to listen. Reach out to CLI today.

Contact Us