Seeing Clearly: How CLI’s AI System Transformed Quality Control

One plant. One challenge. One breakthrough—now transforming many. CLI’s proprietary vision-based AI solution redefines quality control.

Inbound Logistics 3PL Edition, July 2025

Achieving top-tier quality standards was becoming increasingly challenging as production volumes grew and product complexity increased at a facility performing value-add assembly for a leading OEM.

Despite manual inspections and established Poka Yoke systems within the Manufacturing Execution System (MES), existing production processes still failed to reliably detect non-conforming parts before they reached the assembly line. It was clear that relying solely on human oversight to detect errors was no longer sustainable.

THE SOLUTION: VISION-POWERED. AI-DRIVEN. QUALITY ASSURED.

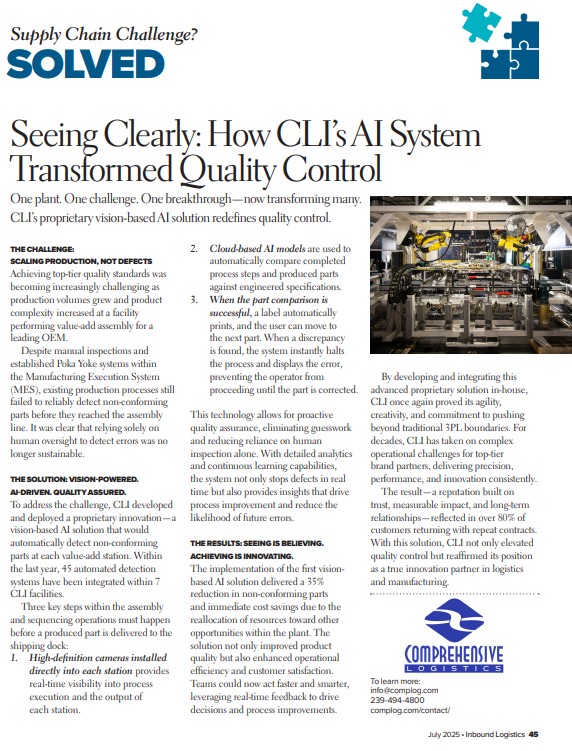

To address the challenge, CLI developed and deployed a proprietary innovation—a vision-based AI solution that is trained to automatically detect non-conforming parts at each value-add station.

| Three key steps within the assembly and sequencing operations must happen before a produced part is delivered to the shipping dock: | |

|---|---|

| 1 | High-definition cameras installed directly into each station provide real-time visibility into process execution and the output of each station. |

| 2 | Cloud-based AI models are used to automatically compare completed process steps and produced parts against engineered specifications. |

| 3 | When the part comparison is successful, a label automatically prints, and the user can move to the next part. When a discrepancy is found, the system instantly halts the process and displays the error, preventing the operator from proceeding until the part is corrected. |

This technology allows for proactive quality assurance, eliminating guesswork and reducing reliance on human inspection alone. With detailed analytics and continuous learning capabilities, the system not only stops defects in real-time but also provides insights that drive process improvement and reduce the likelihood of future errors.

THE RESULTS: SEEING IS BELIEVING. ACHIEVING IS INNOVATING.

The implementation of the first vision-based AI solution delivered a 35% reduction in non-conforming parts and immediate cost savings due to the reallocation of resources toward other opportunities within the plant. The solution not only improved product quality but also enhanced operational efficiency and customer satisfaction. Teams could now act faster and smarter, leveraging real-time feedback to drive decisions and process improvements.

By developing and integrating this advanced proprietary solution in-house, CLI once again proved its agility, creativity, and commitment to pushing beyond traditional 3PL boundaries. For decades, CLI has taken on complex operational challenges for top-tier brand partners, delivering precision, performance, and innovation consistently.

The result—a reputation built on trust, measurable impact, and long-term relationships—reflected in over 80% of customers returning with repeat contracts. With this solution, CLI not only elevated quality control but reaffirmed its position as a true innovation partner in logistics and manufacturing.

| Download Inbound Logistics 3PL Edition

Felecia Stratton, Editor, Inbound Logistics, stated, “By combining forward-thinking strategy with cutting-edge technology and deep logistics expertise, Comprehensive Logistics (CLI) has proven its ability to drive supply chain efficiency for today’s most demanding enterprises. Inbound Logistics is proud to recognize CLI as a 2025 Top 100 3PL Provider.” More information is available at www.inboundlogistics.com. |

|

Comprehensive Logistics (CLI) is built for precision and engineered for the future. When ultimate precision and operational reliability are non-negotiable, CLI delivers. As the most advanced 3PL partner in the industry, we integrate cutting-edge technology, machine learning, and process-driven execution to optimize workflows, eliminate inefficiencies, and ensure flawless delivery. More than a logistics provider, CLI is a true embedded partner – ensuring your supply chain moves with unmatched quality, speed, and control.